|

|

|

|

|

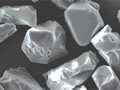

Diamond micropowders АСМ, АСН

ДСТУ 3292-95

|

АСМ Micropowders are produced by static or centrifugal sedimentation method from the fine product remaining after manufacturing of AC grinding powders. Properties of micropowders of various brands are provided by the technological process of their production.

|

|

АСН Submicropowders with sizes of grains from 1 micron and less are produced by classification on high speed centrifugal machines from preliminary processed product of the class minus 1 micron.

|

Types, grit sizes, the characteristic and recommended fields of applications of synthetic diamond micropowders and submicropowders

Type of diamond powder |

Grit sizes |

The characteristic |

The recommended application |

|

Wide Range |

Narrow |

|||

MICROPOWDERS |

||||

АСМ

|

60/28 |

60/40 |

From synthetic diamonds |

Lapping and polishing of ceramics, semi-conductive, etc. materials |

АСН |

From synthetic diamonds of the increased abrasive ability |

Lapping and polishing of firm and superhard difficult-to-machine materials, corundum, ceramics, diamonds, jewels. |

||

SUBMICROPOWDERS |

||||

АСМ5

|

|

1/0,5

0,5/0 |

From synthetic diamonds with the contents of large fractions up to 5% |

Superrfine lapping and polishing of surfaces of products at machining of semiconductive materials and precision parts from other hard-to-machine materials |

АСМ1 |

The Same, with the contents of large fraction up to 1% |

|||

For certification of synthetic diamond micropowders devices LMS 30 and GRANOLOMETR are used. The factory releases powders of the following non-standard grit sizes: 0,25/0, 0,5/0, 3/1, 4/2, 8/4, 10/5, 12/5, 16/8, 20/10, 25/12, 30/20, 40/20

|

|